Insight

Bottleneck and Constraints in Supply Chain Management

Have you ever heard of the terms bottleneck and constraint in supply chain management? These terms, though sometimes used interchangeably, possess distinctive characteristics and exert varied impacts on the flow of production. The 'Theory of Constraints' (TOC), a philosophy introduced by Dr. Eliyahu M. Goldratt, offers a valuable framework for analyzing and enhancing systems by pinpointing and addressing the most limiting factors. In this post, we delve into the differences between bottlenecks and constraints and explore how production planning can aid in overcoming these challenges.

Bottleneck vs constraint

A bottleneck in supply chain management is identified as a specific point of congestion where throughput is limited due to lack of capacity or efficiency. Typically, this is a physical location, like a machine that's unable to meet demand, leading to pile-ups and extended lead times in production.

On the other hand, a constraint encompasses any limitation or obstacle that prevents the supply chain from reaching its full potential, ranging from physical limitations like production capacity and storage space to non-physical ones such as legislation, policies, and labor or capital availability. TOC suggests that there is at least one limiting factor in every complex system that determines the strength of the entire system.

While a bottleneck can be seen as a type of constraint, not every constraint is a bottleneck. Bottlenecks are generally temporary and subject to change with operational modifications or demand shifts. Constraints, however, can be more enduring and require strategic management to overcome.

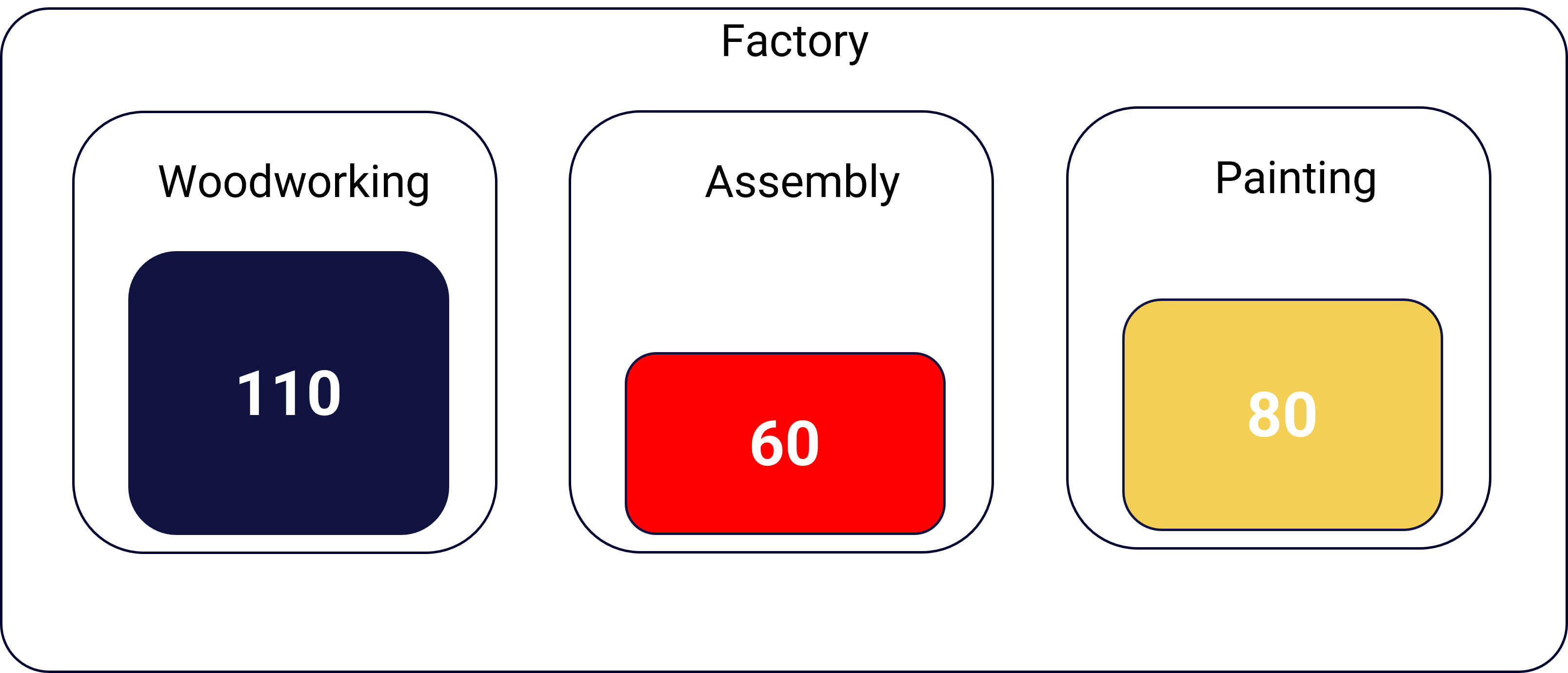

Let's illustrate this with an example. Imagine a factory that produces chairs involving steps like woodworking, assembly, painting, and packaging. The assembly department (the red block in the diagram) can assemble 60 chairs per hour, while the painting department (the yellow block) can handle 80 chairs per hour. The woodworking department (the blue block) has a capacity of 110 chairs per hour.

The assembly department represents a bottleneck as it cannot keep up with the woodworking department, leading to an accumulation of unassembled chairs.

According to TOC, the focus should be on this bottleneck to improve throughput.

If the factory only has orders for 50 chairs per hour, then capacity doesn't pose a constraint; the limiting factor may be external, such as market demand or material supply restrictions.

To address the bottleneck, additional shifts in the assembly department could be introduced, or investment in faster assembly equipment could be made to balance the process with other departments.

However, for a market-related constraint, simply improving internal processes may not suffice. Here, TOC would encourage an adjustment in marketing strategy to boost demand or diversify the supply chain to avert material shortages.

Short-Term Production Planning to Mitigate Bottlenecks

Eradicating bottlenecks in a production process is a challenge that often cannot be achieved in the short term. Yet, production planners can employ tactics to lessen the impact of bottlenecks that cannot be immediately removed:

- Prioritize orders based on the bottleneck: Focus on local optimization by scheduling orders to utilize the full capacity of the bottleneck resource.

- Balance material and product flow: Maintain a balanced supply and flow of materials throughout the production line to minimize waiting times at the bottleneck.

- Leverage buffer stocks: Keep a stock of critical semi-finished goods to ensure production continues smoothly amidst delays, acting as a buffer against fluctuations in the production process.

By implementing these strategies, businesses can diminish the adverse impact of bottlenecks and bolster overall production efficiency. It calls for proactive planning and a flexible production scheduling system ready to swiftly respond to changes and challenges.